This material is from [ http://www.ar15.com/forums/t_6_42/281056_.html ]

The poster/author was AssaultRifler on 5/25/2009

The material was so well described I wanted to make a copy to be sure it would be around, when I

wanted to review it.

So all credit goes to the young man that did the orgional work for this post.

=======================

Decided it's time to reload 380ACP and I'll be doing it on the 550B.

I'll be doing this from scratch, working up and then test firing loads

then settling on the load I want. Then I'll crank them out in massive

quantities.

If you ever find yourself with a bunch of pistol components and a

Dillon 550B and wondered what it takes to make ammo, read and find out

Part 1 - Gathering the components

First thing I did was gather all my small primer pickup tubes and filled them up, I had 11 in all

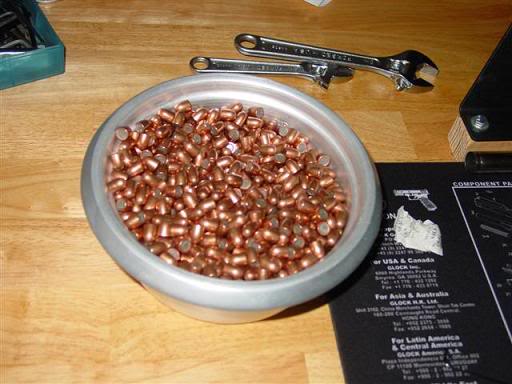

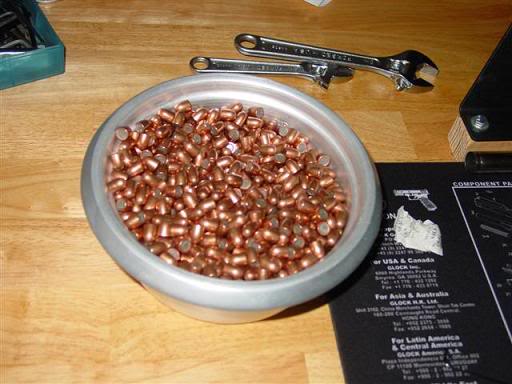

Next thing I did was go and raid my bullet hoard for 380ACP projectiles.

I found some, they were still packaged the way I got 'em off EE 2-3

years ago

I filled the bullet tray of the 550 with some

And put some of the rest in a container and left the ones that came in the case in the case.

That's a lot of bullets. I wondered for a second if I had enough brass,

primers, and powder to load them all. Then I realized what

a silly question

Before I decide on a load I have to know what I had bullet wise, I

weighed a couple and they were 95 grain FMJ's. The scale says 94.6

grains. Yeah, you'll find that bullets hardly weigh their stated weight

exactly. Their weight will vary.

Part 2 - Making test loads

OK, I have 95 grain projectiles and I use Accurate Arms powder. So I went to http://www.accuratepowder.com/wp-content/uploads/2011/01/accurate_load_data_3.5.pdf and found this entry:

No.5 95 SIE FMJ 4.3 784 4.8 891 14,000 0.945

I have AA#5. So I decided to make the follow test loads:

10 x 4.3 grains AA#5

10 x 4.5 grains AA#5

10 x 4.7 grains AA#5

10 x 4.8 grains AA#5

The next step was to convert the Dillon 550 progressive press over to 380ACP

Initially it was like this:

The sizing die was already adjusted from the last time I did 380. So I didn't have to do anything special at station 1.

Next step was to adjust the case mouth belling, that's done at station 2

with the powder funnel. It was set from the last reloading session but

I needed to adjust it some. This is always a minor PITA. Anyway, when I

had enough bell, I moved on to station 3 and seated a bullet in a sized

but unprimed and uncharged case

My goal at this point is to get the cartridge OAL adjusted. From

another reloading manual the min cartridge OAL is 0.940" and the max is

0.984". I figured somewhere halfway, around 0.960" would be perfect.

After twiddling with it I got it at .962" and figured it was close

enough and locked down the die rings.

Note you can see the case mouth belling in this pic. It wont be removed until the case is taper crimped

Here's the dummy round taper crimped

Here's the dummy round in the case gage being checked

Next step was to fill the priming feed system with small pistol primers

which was easy since I already filled the tubes. Then I calibrated the

powder measure to drop 4.3 grains of AA#5

The first live round is always exciting and should be checked

Looks good. I finished the other 9 with the 4.3 grain charge

Then I did 10 rounds of 4.3, 4.5, 4.7, and 4.8 grains

I marked the cases in case I dropped the box. My method is the more

marks on a case the more powder it has. the 4.3 grain loads have no

marks, the 4.5 have one ticky mark, the 4.7 have 2 ticky marks, the 4.8

grain loads have an "X"

That's it for now, nothing more I can do until I test fire the loads

Part 3 - Range Session

Went to the range this morning to try the new reloads. A little range

session planning is in order here. You don't want to just show up, pop

off a few

rounds, then head back to the reloading bench. You need a methodology

that will allow you to determine what powder charge you're going to

settle on.

The method I follow is:

1) Warm up by shooting some known good ammunition. This gets you in the

groove and ensures the gun is in good working order. If you just

started popping off your test loads and you get a jam, is it the gun or

the loads? If your groups suck is it because the loads suck or you're

just a bit rusty? Warming up helps in both regards.

2) Clean up the brass from the warm up session

3) Shoot the test loads with the lowest powder charge first at a target,

then the ones with the next higher powder charge, and so on until

you've

shot all your test loads. Before moving on to the the loads with the

next higher powder charge, retrieve the brass from the previous test

loads. Examine them for signs of over pressure, if you see any then

STOP! If you have any test loads left you'll have to pull the bullets

and dump the powder.

4) When it's all done, look at the target, which powder charge gave you

the tightest group and still cycled the gun? That's the load you want to

crank out in quantity.

Here's how my session went. I brought two guns and went through the methodology for both.

The guns are a Sig 230 and a Beretta 84F. I bring my magazines already

loaded to the range so I don't have to waste time loading them

at the range. I brought a cheap cigar, a JR alternative.

Testing with the Sig 230

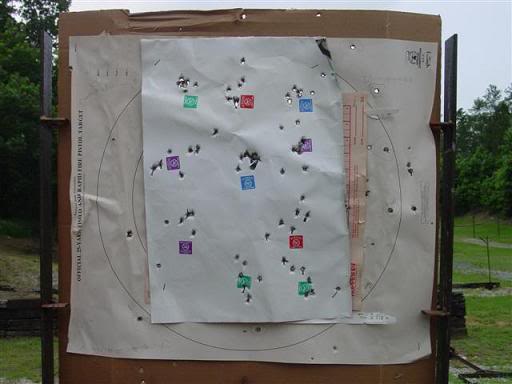

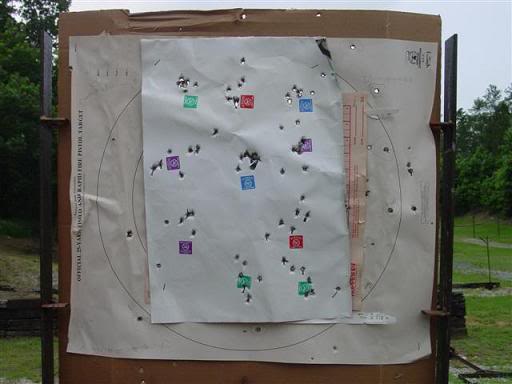

I set up the target for the practice session with the Sig 230. The target was at 7 yards

Then I practiced away. Some groups are better than others, The one in the middle kicks butt. Practice makes perfect!

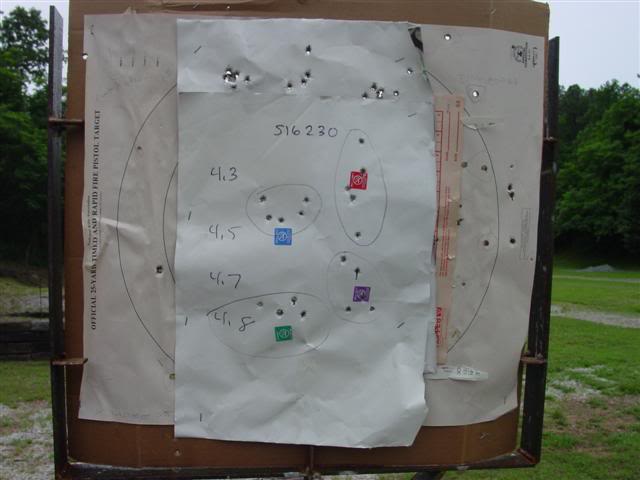

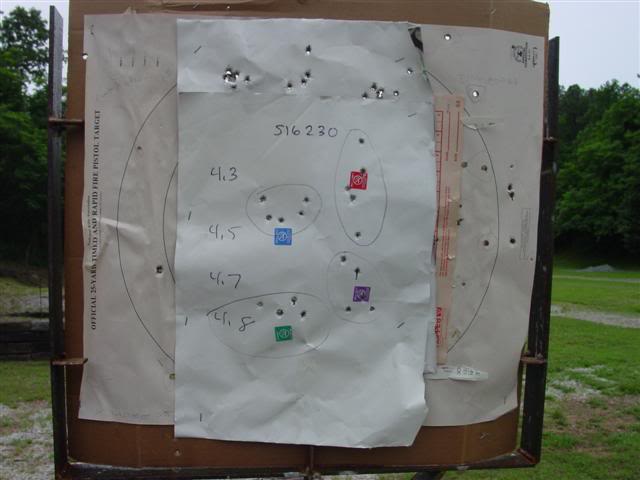

Next I slapped on a new target, with a bullseye to shoot at for each

powder charge. I went through the test loads starting with the 4.3 grain

load and worked up until I finished them all. Here's the results:

Here's the brass

All the brass looked ok, no signs of over pressure. All rounds cycled

perfectly, no jams. Based on the results so far I'm liking the 4.7

grain loads. I already lost 2 pieces of brass to the Brass Gods. I

always let the Brass Gods take what they want. They're firm but fair.

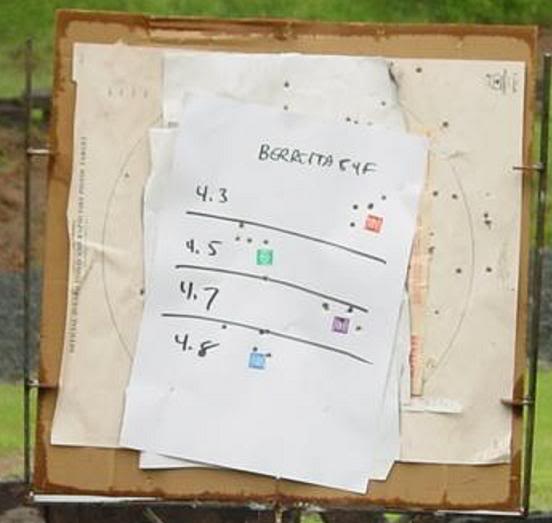

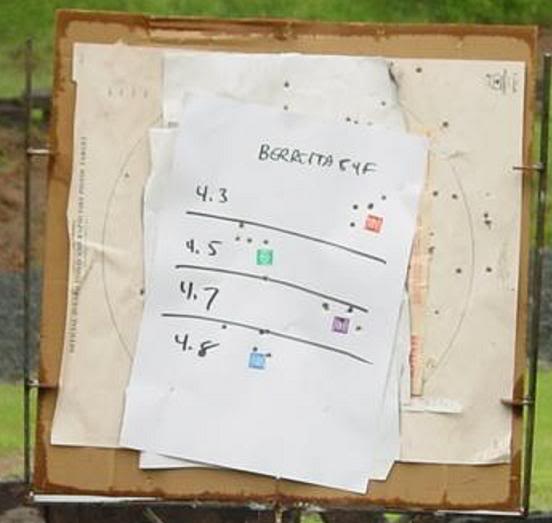

Testing with the Beretta 84F

I went through the same process with the 84F that I did with the Sig. Started out by popping off some mags to get warmed up.

It started to rain. The rain dampened my target, but not my spirits. I continued on.

I shot away at 4 different bullseyes, 1 for each powder charge.

I like the 4.7 grain charge with the Beretta 84F as well

And the brass is looking OK as well. Overall the Brass Gods demanded a sacrifice of 4 pieces of brass from me.

That settles it, my load is going to be 4.7 grains of AA#5

Hopefully this is a good example of how to work up and ultimately choose

a load. There's no substitute for doing your homework. Don't just pick

a load from a book or somewhere you found online and then crank out a

bunch of rounds. Use other people's data to verify your own findings

not as a way to weasel out of working up the loads yourself.

Part 4 - Production

I

calibrated the powder measure to toss 4.7 grains of AA#5 and

methodically cranked out round after round. Here's what my current work

environment looks like. The motor oil is straight 30 weight and used

to lube the ram on the 550B. Note the new to me Dillon press mounted

wrench set. It saves a lot of time trying to find the right allen

wrench.

I ran out

of the initial 1100 primers I had loaded up in the tubes and here's the

result so far. I won't consider these "done" until I check them with a

case gage, but I'll do that after loading up all the projectiles.

I raided my primer stash and got another 3K out ready for action!

I'm up to 1900 or so now, that's a lot of cranking!

No big issues. I found a 1/2 dozen 9mm cases in my 380 brass stash, as

well as a 9x19 Mak case. They don't fit in the 380ACP resizing

die so they're caught immediately. The 550B is staying relatively clean

powder dribbling wise, but I get about 5 spent primers out of every 100

that miss the primer catch bin and end up on the table top, floor, etc.

Here's a closeup, suitable for reloading

Finished!

I cranked out the final round Saturday sometime. Ended up with about 2900 or so since I shot

some at the range last week. Here's the final batch

Like

I said I don't consider them "done" until every round is checked with a

case gage. It's a good habit to get into and the results

pay off. It takes a while but it makes your reloads virtually 100% reliable.

Here's what I found:

The

2 on the left were sized and primed cases, but case mouths not belled.

I can only surmise I dropped these into the output bin along

with some finished rounds and didn't notice. 380ACP cases are tiny and my fingers and big and fat, they're hard to hold on to!

Third from the left is a 32ACP case that thought it'd be funny to sneak

into my 380ACP brass stash. Who's laughing now? He looks like an

idiot!

Next 2 are missing the primer

The last 4 failed to seat all the way in the case gage, mostly due to dinged up rims.

I pulled all the bullets and made 7 good rounds with the salvaged

projectiles. I'm so cheap I even saved the live decapped primers

See you at the range